*Imininingwane

Ulayini wokukhiqiza wephaneli ye-Sandwich uklanyelwe ngokukhethekile ukukhiqiza ibhodi eliyinhlanganisela yokufakwa kwe-insulation. Ngesistimu yokulawula isivinini engenazinyathelo, Iyakwazi ukukhiqiza iphaneli ehlanganisiwe ehlanganisiwe kahle ngesikhathi esisodwa. Umshini wokwenza i-sandwich panel roll ube yithuluzi elibalulekile ekwakheni amaphaneli ophahla namaphaneli odonga ezitshalweni nasezindaweni zokugcina impahla, phakathi kwezinye izakhiwo.

*Izici

*Izici

1. Amandla e-motor we-sandwich panel form form line line-4k futhi isivinini sokukhiqiza sifinyelela ku-6mmln. Ngohlelo lokulawula isivinini esingenasinyathelo, ukusebenza kahle komugqa wokwenza umqulu kungakhethwa ngaphakathi kwe-O-6m mm.

2. uBen okhiqiza iphaneli yesemishi le-EPS, isivinini ngokuvamile silawulwa ku-2-6 m mm. Izoba ngaphansi kancane ekwenzeni ibhodi le-rock wool (kuya ngezidingo zangempela)

3. Ulayini wokukhiqiza wephaneli oyinhlanganisela Ifakwe i-K.9 glue metering pump, enejubane eliphansi elijikelezayo kanye nokunemba okuphezulu Iglue yondliwa ngenani lika-0.1-2.0 kg mm. Ilawulwa yi-frequency converter.

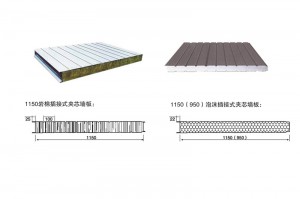

4. Ubukhulu bephaneli ehlanganisiwe iyunithi yokwakha umqulu ingakhiqizwa ihlukahluka kusuka ku-50mm kuya ku-0mm. Ngokulungisa i-rack engaphezulu nephansi, kanye nebanga phakathi kwesibambi sokusika kanye ne-rack feeding rack, singathola amabhodi amasemishi anobukhulu obuhlukahlukene kanye nokucaciswa.

5. Isamba somthamo ofakiwe: 34KW”; isisindo esiphelele (kuhlanganise nezinsiza): 17.5t.

6. Ubukhulu bomshini wokwenza umqulu wephaneli: 12500 (16000 yamabhodi woboya bedwala) X2200X2800; umqulu wangaphambili wephaneli lesemishi le-EPS lezinhlobo ezi-5 wamukela amashafu erabha angama-23 kanye namashubhu ayizikwele ayi-160X80 anogqinsi luka-6mm; i-roll yangaphambili yezinhlobo ezingu-7 ze-rock wool panel isebenzisa amashafti erabha angama-43, futhi i-glue suppb engaphezulu nephansi ezimele Ifakwe ibhande lokuhambisa lephaneli le-rock elingu-7m, ububanzi bomshini wokushayela bube ngu-30mm; ubude bohlaka lomshini Bufika ku-Qm; i-roll yangaphambili Ihlanganiswe namashubhu ayisikwele angu-180X80 ukuqina kwawo Kungu-8mm.

*Izidingo zezimboni

Amafekthri lapho kusetshenziswa khona imishini yethu yokwakha amadekhi ensimbi angaba uphahla oluyisicaba noma uhlobo lophahla olutshekile. Ukuphakama kwe-cornice kufanele kube kukhulu kune-3m, futhi ububanzi obusebenzayo kufanele okungenani bube ngu-45m. Iphansi lefekthri kufanele libe yisicaba futhi libe nokhonkolo. Ukuze uthole isisekelo somugqa wokwenza umqulu, kuyadingeka ukuthi uklanywe ngokuhambisana nemidwebo futhi ukhishwe ngaphambi kokuba imishini ifike. Ugesi udingeka ube ngu-380 kanti amandla afakiwe esewonke Angu-34kw. Kuyadingeka ukuthi i-facto ifakwe 0.4-0.6MPa ocindezelwe umoya wokuhambisa umoya kanye namadivayisi okukhanyisa. Umshini wokwenza umqulu wabelana ngokuphakelwa kwamandla okufanayo namadivayisi asizayo. Ukushintshashintsha kwamandla kagesi akufanele kube ngaphezu kuka-l0%, noma kungase kuholele ekusebenzeni okungavamile kwesistimu.

I-stroke ayikho ngaphansi kwama-29m, umthwalo wenqubo yokuphakamisa mkhulu kuno-5000kg, futhi ukuphakama kokuphakamisa Akukho ngaphansi kuka-3.Qm. Ngokukhiqizwa nokugcinwa kwansuku zonke, abantu abangaba ngu-8.10 bayadingeka, kanye nama-opharetha angu-3.4 kwezinye izinqubo ezibalulekile ezifakiwe.

*Uhlelo lokusebenza

Idivayisi eseceleni yokuvala yephaneli ye-rockwool

ukusika uhlelo

Amaphampu enjoloba amane alawulwa izinjini ezimbili

Ishaft yerabha ewugqinsi

Idivayisi yokugoqa kagesi

umshini wokwenza roll

uhlelo lokulawula

Ibhande lokuthutha elinwetshiwe

*Letha izimpahla

♦ UMLANDO WENKAMPANI:

I-Hebei Xinnuo Roll Forming Machine Co., Ltd., ayikhiqizi nje kuphela izinhlobo ezahlukene zemishini yokwenza ama-roll, kodwa futhi ithuthukisa imigqa yokukhiqiza ehlakaniphile eyenza umqulu othomathikhi, imishini ye-C&Z yomumo we-purline, imigqa yomshini wokwenza i-highway guardrail roll, imigqa yokukhiqiza iphaneli isangweji, ukudeka. Imishini yokwakha, imishini yokufaka i-keel elula, imishini yokwenza izicabha ze-shutter slat, imishini yokukhipha amanzi, imishini yokufaka udoti, njll.

Izinzuzo Zokwenza I-Roll Ingxenye Yensimbi

Kunezinzuzo ezimbalwa zokusebenzisa ukwenza ama-roll kumaphrojekthi akho:

- Inqubo yokwenza umqulu ivumela imisebenzi efana nokubhoboza, ukuchopha, nokushisela ukuthi kwenziwe emgqeni. Izindleko zomsebenzi kanye nesikhathi sokusebenza kwesibili kuyancishiswa noma kuqedwe, kunciphisa izindleko zengxenye.

- Amathuluzi e-roll form kuvumela izinga eliphezulu lokuguquguquka. Isethi eyodwa yamathuluzi efomu lokugoqa izokwenza cishe noma yibuphi ubude besigaba esiphambanayo esifanayo. Amasethi amaningi wamathuluzi ezingxenye ezihlukene zobude awadingeki.

- Inganikeza ukulawula okungcono kwe-dimensional kunezinye izinqubo zokwenza insimbi eziqhudelanayo.

- Ukuphindaphinda kungokwemvelo enqubweni, okuvumela ukuhlanganisa kalula izingxenye ezakhiwe emkhiqizweni wakho oqediwe, nokunciphisa izinkinga ngenxa yokwakhiwa kokubekezelelana “okujwayelekile”.

- Ukwakhiwa kwamaroli ngokuvamile kuyinqubo yesivinini esiphezulu.

- Ukwakhiwa kweroli kunikeza amakhasimende ukuqedwa okuphezulu kwendawo. Lokhu kwenza umqulu ukwakha inketho enhle kakhulu yezingxenye zensimbi engagqwali zokuhlobisa noma izingxenye ezidinga ukuqedwa njenge-anodizing noma i-powder coating. Futhi, ukuthungwa noma iphethini kungenziwa kugoqwe ebusweni ngesikhathi sokwenza.

- Ukwakhiwa kwamaroli kusebenzisa izinto ngokuphumelelayo kunezinye izinqubo eziqhudelanayo.

- Amajamo akhiwe ngama-roll angathuthukiswa ngezindonga ezincanyana kunezinqubo eziqhudelanayo

Ukwakhiwa kwamarola kuyinqubo eqhubekayo eguqula insimbi yeshidi ibe yijamo eyenziwe ngobunjiniyela kusetshenziswa amasethi alandelanayo amaroli ahlanganisiwe, ngalinye elenza izinguquko ezikhulayo kuphela efomini. Isamba salezi zinguquko ezincane efomini iphrofayili eyinkimbinkimbi.

-

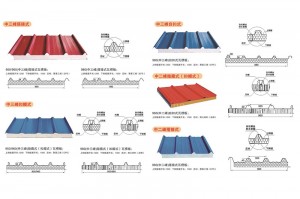

umshini wokwenza iphaneli lokuma lomthungo

-

umshini wokwenza i-wall panel roll

-

onguthelawayeka guardriall roll ukwakha umshini onguthelawayeka...

-

umshini wokwenza i-greenhouse gutter channel

-

manual sheet metal curving machine tile manufac...

-

Amaphaneli Okwenza Umshini Waphansi Roll forming Machine iron ...