I-Xinnuo Galvanized iron forming machine,

Umshini wokwenza umqulu weshidi lensimbi,

| CHA. | Ipharamitha eyinhloko ye-Botou city canton fair authentication 828 automatoc press blue okwenza amajoists acwebezelisiwe ensimbi ophahleni lukathayela ophuma emshinini onece | |

| 1 | Ifanele ukucutshungulwa | Ipuleti lensimbi elinemibala |

| 2 | Ububanzi bepuleti | 1000mm |

| 3 | Ubukhulu bepuleti | 0.3-0.7mm |

| 4 | I-De-coiler | Imanuwali yokuqala, ingalayisha amathani ayi-5 impahla eluhlaza |

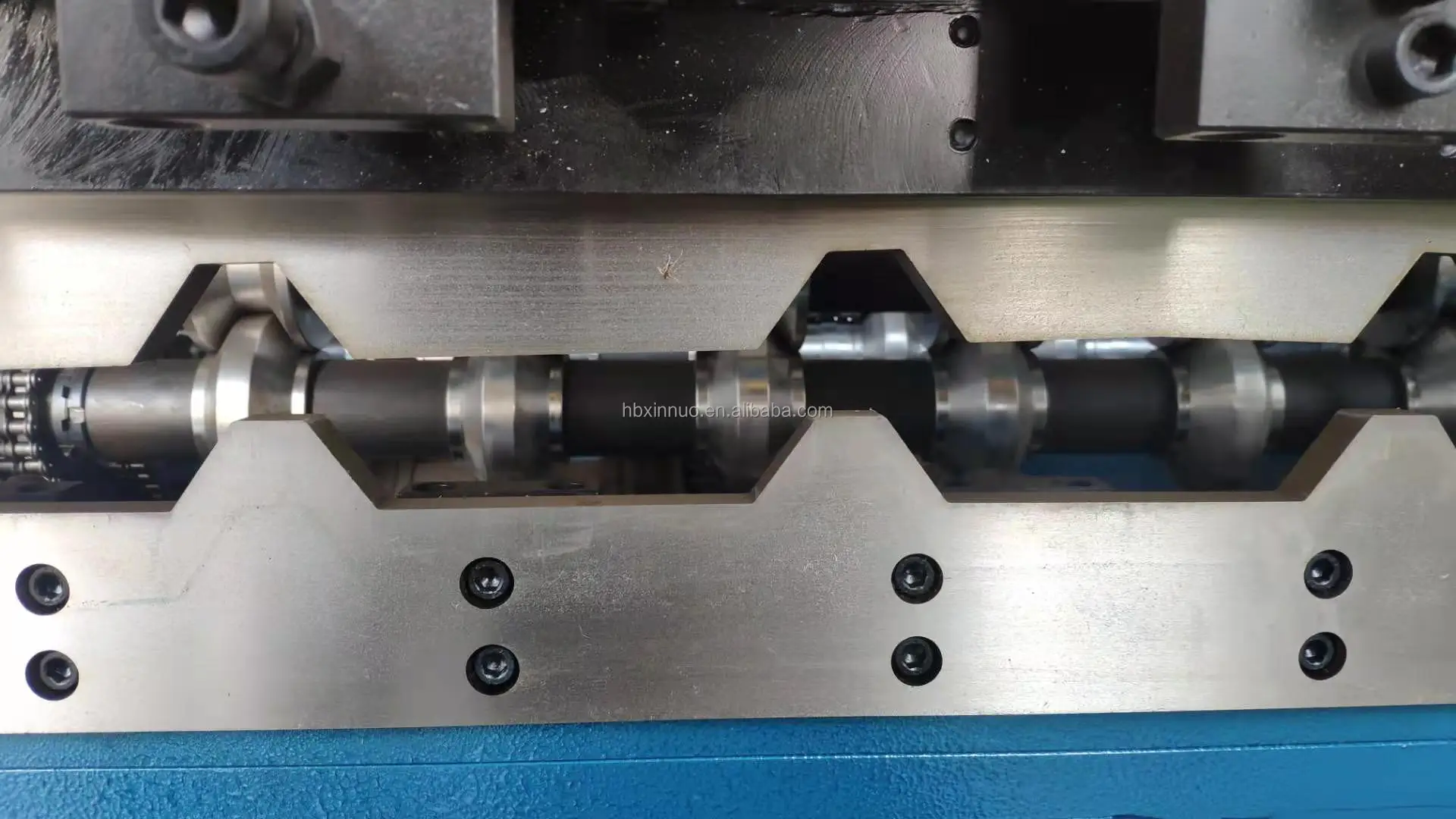

| 5 | Amarola okwenza | 12 imigqa |

| 6 | Ububanzi be-roller | 80mm |

| 7 | Izinto ezigoqayo | I-Carbon Steel 45# |

| 8 | Amandla emoto amakhulu | 4kw |

| 9 | Ukukhiqiza | 0-3m/min |

| 10 | Indlela yokusika | Ukusika insika ye-Hydraulic kanye nomhlahlandlela |

| 11 | Impahla ye-blade yokusika | Cr12 |

| 12 | Amandla okusika ama-hydraulic | 3 kw |

| 13 | Icubungula ukunemba | Ngaphakathi kwe-1.00mm |

| 14 | Isistimu yokulawula | Ukulawulwa kwe-Delta PLC |

| 15 | Iphaneli eseceleni yomshini | 14mm |

| 16 | Isakhiwo esikhulu somshini | 300 H insimbi |

| 17 | Isisindo | Cishe i-4.0T |

| 18 | Ubukhulu | 7.0*1.5*1.55m |

| 19 | Amandla kagesi | 380V 50Hz 3 izigaba (ezishintshayo njengezidingo) |

| 20 | Isitifiketi | CE/ISO |

| 21 | Ngokwezifiso | Ngokwezidingo zekhasimende |

| Imininingwane yokupakisha: | Umshini omkhulu unqunu, ibhokisi lokulawula ikhompuyutha ligcwele ifreyimu yokhuni. |

| Umshini oyinhloko unqunu esitsheni, ibhokisi lokulawula ikhompyutha ligcwele ukupakishwa ngokhuni. | |

| Imininingwane Yokulethwa: | izinsuku ezingu-20 |

Ngokuthuthuka okuqhubekayo kwesayensi nobuchwepheshe, imishini ehlukahlukene ekukhiqizeni izimboni nayo ivuselelwa njalo. Phakathi kwabo, umshini wokwenza ikhoyili yensimbi, njengethuluzi elibalulekile lokukhiqiza, usetshenziswa kabanzi emikhakheni eminingi. Lesi sihloko sizochaza kabanzi ngomshini wokwenza amashidi ensimbi.

I. Uhlolojikelele

Umshini wokwenza ikhoyili yensimbi uyisisetshenziswa esicubungula amakhoyili ensimbi abe yizimo nokucaciswa okuhlukahlukene. Umgomo wayo wokusebenza ukucubungula ishidi lensimbi libe yisimo nosayizi odingekayo ngokusebenzisa uchungechunge lokwakha isikhunta kanye nemishini yemishini. Lolu hlobo lwemishini lusetshenziswa kakhulu ekwakhiweni, ekwakhiweni kwezimoto, ezintweni zikagesi zasendlini nakweminye imikhakha.

2. Isimiso sokusebenza

Umgomo wokusebenza womshini wokwenza amashidi ensimbi uhilela ikakhulukazi lezi zinyathelo ezilandelayo:

Ukuqaqa: Beka ikhoyili yeshidi lensimbi kudivayisi yokuqaqa bese uyithumela endaweni eyakhiwe kuyo ngomshini wokudonsa.

Ukubunjwa: Endaweni yokubunjwa, ikhoyili yensimbi yeshidi idlula ochungechungeni lokufa bese icutshungulwa ibe yisimo nosayizi odingekayo. Isikhunta esisakhayo singashintshwa njengoba kudingeka ukuze sivumelane nezincazelo ezihlukahlukene kanye nokuma kwamakhoyili eshidi lensimbi.

Ukushisela: Ngesikhathi sokubunjwa, uma amakhoyili ensimbi edinga ukushiselwa ndawonye, lokhu kungafezwa ngomshini wokushisela. Idivayisi yokushisela ingalungiswa njengoba kudingeka ukuze ivumelane nezidingo ezahlukene zokushisela.

I-galvanizing: Ngemva kokubunjwa nokushisela, ikhoyili yeshidi lensimbi ingafakwa uthayela ukuze ithuthukise ukumelana nokugqwala kwayo nempilo yokusebenza kwayo. Idivayisi yokufaka uthayela ingalungiswa njengoba kudingeka ukuze ihambisane nezidingo ezahlukene zokugalela.

Ukupholisa: Ngemva kokuqeda inqubo yokufaka uthayela, ishidi lensimbi lidinga ukupholiswa ukuze lizinzise futhi lithuthukise ikhwalithi yalo. Iyunithi yokupholisa ingalungiswa njengoba kudingeka ukuze ihambisane nezidingo zokupholisa ezihlukene.

Ukuhlehlisa emuva: Ekugcineni, amashidi ensimbi agayiwe ayagoqwa ukuze acutshungulwe noma athuthwe. Umshini wokusonta ungalungiswa njengoba kudingeka ukuze uhlanganise amakhoyili ensimbi anemininingwane ehlukene nosayizi.

3. Izinkambu zokufaka isicelo

Njengomshini wokukhiqiza obalulekile, umshini wokwenza amashidi ensimbi owenziwe ngensimbi usetshenziswa kabanzi emikhakheni eminingi. Nazi ezinye zezindawo eziyinhloko zokufaka isicelo:

Inkambu yokwakha: Emkhakheni wokwakha, imishini yokwakha amashidi ensimbi ethathiwe isetshenziswa ikakhulukazi ukwenza uphahla, amaphaneli odonga kanye nezinye izinto zokwakha ezinobunjwa obuhlukahlukene kanye nokucaciswa. Ngenxa yokumelana nokugqwala okuhle kakhulu kanye nekhwalithi enhle yokubukeka, isetshenziswa kabanzi ezinhlotsheni ezahlukahlukene zamaphrojekthi wokwakha.

Inkambu yokukhiqiza izimoto: Emkhakheni wokukhiqiza izimoto, imishini yokwakha amashidi ensimbi isetshenziswa ikakhulukazi ukwenza imizimba yezimoto, izicabha nezinye izinto. Ngenxa yamandla ayo amahle kakhulu nokuqina, ihlangabezana nezidingo eziphakeme zokukhiqiza izimoto.

Inkambu yebhizinisi lezinto zikagesi zasekhaya: Emkhakheni webhizinisi lezinto zikagesi zasekhaya, imishini yokwakha amashidi ensimbi isetshenziswa ikakhulukazi ukwenza amakesi ezinto zikagesi zasendlini kanye nezingxenye zomumo nokucaciswa okuhlukahlukene. Ngenxa yokubukeka kwayo okuhle nokungagqwali, ingahlangabezana nezidingo zemishini yasendlini.

Eminye imikhakha: Ngaphezu kwalezi zinkambu ezingenhla, imishini yokwakha amashidi ensimbi ethathiwe isetshenziswa kabanzi embonini yamakhemikhali, i-petroleum, imboni yokukhanya kanye neminye imikhakha lapho kudingeka khona imikhiqizo yensimbi yokwakheka nokucaciswa okuhlukahlukene.

4. Isiphetho

Ukufingqa, umshini wokwenza ikhoyili yensimbi, njengento ebalulekile yokukhiqiza, usetshenziswa kabanzi emikhakheni eminingi. Njengoba ubuchwepheshe buqhubeka buthuthuka, ukusebenza kwayo kanye nekhwalithi nakho kuthuthuka njalo. Ngokuzayo, ngoshintsho ekudingeni izimakethe kanye nokuthuthuka kwezobuchwepheshe, imishini yokwenza amashidi ensimbi amagalani izoqhubeka nokudlala indima ebalulekile ekuhlinzekeni ukwesekwa okuqinile kokukhiqizwa nokuthuthukiswa kwezimboni ezihlukahlukene.

♦ UMLANDO WENKAMPANI:

I-Hebei Xinnuo Roll Forming Machine Co., Ltd., ayikhiqizi nje kuphela izinhlobo ezahlukene zemishini yokwenza ama-roll, kodwa futhi ithuthukisa imigqa yokukhiqiza ehlakaniphile eyenza umqulu othomathikhi, imishini ye-C&Z yomumo we-purline, imigqa yomshini wokwenza i-highway guardrail roll, imigqa yokukhiqiza iphaneli isangweji, ukudeka. Imishini yokwakha, imishini yokufaka i-keel elula, imishini yokwenza izicabha ze-shutter slat, imishini yokukhipha amanzi, imishini yokufaka udoti, njll.

Izinzuzo Zokwenza I-Roll Ingxenye Yensimbi

Kunezinzuzo ezimbalwa zokusebenzisa ukwenza ama-roll kumaphrojekthi akho:

- Inqubo yokwenza umqulu ivumela imisebenzi efana nokubhoboza, ukuchopha, nokushisela ukuthi kwenziwe emgqeni. Izindleko zomsebenzi kanye nesikhathi sokusebenza kwesibili kuyancishiswa noma kuqedwe, kunciphisa izindleko zengxenye.

- Amathuluzi e-roll form kuvumela izinga eliphezulu lokuguquguquka. Isethi eyodwa yamathuluzi efomu lokugoqa izokwenza cishe noma yibuphi ubude besigaba esiphambanayo esifanayo. Amasethi amaningi wamathuluzi ezingxenye ezihlukene zobude awadingeki.

- Inganikeza ukulawula okungcono kwe-dimensional kunezinye izinqubo zokwenza insimbi eziqhudelanayo.

- Ukuphindaphinda kungokwemvelo enqubweni, okuvumela ukuhlanganisa kalula izingxenye ezakhiwe emkhiqizweni wakho oqediwe, nokunciphisa izinkinga ngenxa yokwakhiwa kokubekezelelana “okujwayelekile”.

- Ukwakhiwa kwamaroli ngokuvamile kuyinqubo yesivinini esiphezulu.

- Ukwakhiwa kweroli kunikeza amakhasimende ukuqedwa okuphezulu kwendawo. Lokhu kwenza umqulu ukwakha inketho enhle kakhulu yezingxenye zensimbi engagqwali zokuhlobisa noma izingxenye ezidinga ukuqedwa njenge-anodizing noma i-powder coating. Futhi, ukuthungwa noma iphethini kungenziwa kugoqwe ebusweni ngesikhathi sokwenza.

- Ukwakhiwa kwamaroli kusebenzisa izinto ngokuphumelelayo kunezinye izinqubo eziqhudelanayo.

- Amajamo akhiwe ngama-roll angathuthukiswa ngezindonga ezincanyana kunezinqubo eziqhudelanayo

Ukwakhiwa kwamarola kuyinqubo eqhubekayo eguqula insimbi yeshidi ibe yijamo eyenziwe ngobunjiniyela kusetshenziswa amasethi alandelanayo amaroli ahlanganisiwe, ngalinye elenza izinguquko ezikhulayo kuphela efomini. Isamba salezi zinguquko ezincane efomini iphrofayili eyinkimbinkimbi.

-

Intengo Ephansi Kakhulu Xn Z-Lock Automatic EPS kanye ...

-

Idizayini Evuselelekayo ka-2023 Pop up 20/40 FT Conta...

-

Ifektri ngqo i-China Modern Villa Style Metal...

-

I-Factory Supply Fully Automatic Roll Yakha i-Mac...

-

Ikhwalithi enhle kakhulu ye-XN1000 Glazed Roof Tile Makin...

-

I-China Intengo Eshibhile I-Customizable Fireproof Galval...