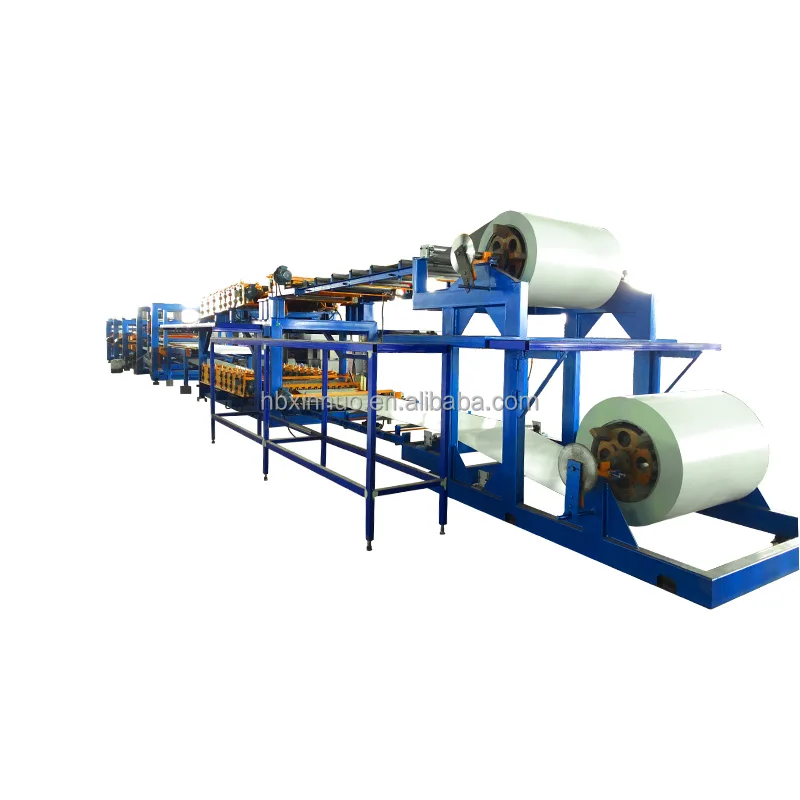

| Cha. | ipharamitha eyinhloko yomugqa womshini wokwenza iphaneli yeSandwich | ||

| 1 | Ifanele ukucutshungulwa | Ipuleti lensimbi elinemibala | |

| 2 | Ububanzi bepuleti | 1000&1200mm | |

| 3 | Amarola | 17-44 imigqa | |

| 4 | Ubukhulu | 38.0*2.25*2.5m | |

| 5 | Amandla | 30kw | |

| 6 | Ubukhulu bepuleti | 0.3-0.8mm | |

| 7 | Ukukhiqiza | 2-6m/min | |

| 8 | Ububanzi be-roller | Φ90 mm | |

| 9 | Isisindo | Cishe ngo-15 T | |

| 10 | Amandla kagesi | 380V 50Hz 3 izigaba | |

| 11 | Izinto zepuleti lokusika | Cr12 | |

| 12 | Icubungula ukunemba | Ngaphakathi kwe-1.00mm | |

| 13 | Isistimu yokulawula | Ukulawulwa kwe-PLC | |

| sandwich panel amazinga | |

| Ubude | Ubude bokusika okuncane: 3 m Ubude besitaki esikhulu: 15 m |

| izindinganiso zempahla eluhlaza | |

| Ubukhulu bekhoyili | 0.4 ~ 0.6mm (ikhoyili kufanele ibe flat, ayikho i-arch kanti ezinye ziveza izinkinga.) |

| Amandla okukhiqiza ikhoyili | 235MPa |

| Ubukhulu bekhoyili yobubanzi | bheka imidwebo enemininingwane yephrofayili. |

| Isisindo sekhoyili esibalulekile | 5 T |

| Ikhoyili yensimbi ububanzi bangaphakathi | Φ508,Φ610 mm |

| Izinto eziyinhloko ze-EPS | |

| ukuminyana | ≥18Kg/m3 |

| isilinganiso esiqondile | ≤1mm/m |

| i-arch degree | ≤3mm/m |

| indawo yephaneli | kufanele kube flat akukho degree flat ≤1.5mm/m, |

| sandwich panel ubude | ubude ngaphezu kwamamitha angu-5 |

| impahla yoboya | |

| ubude befiber | ≥100mm |

| ukuminyana kwe-cubage | ≥100Kg/m3 |

| sandwich panel ubude | ≥3 amamitha |

| Imininingwane yokupakisha: | Umshini omkhulu unqunu, ibhokisi lokulawula ikhompuyutha ligcwele ifreyimu yokhuni. |

| Umshini oyinhloko unqunu esitsheni, ibhokisi lokulawula ikhompyutha ligcwele ukupakishwa ngokhuni. | |

| Imininingwane Yokulethwa: | izinsuku ezingu-20 |

♦ UMLANDO WENKAMPANI:

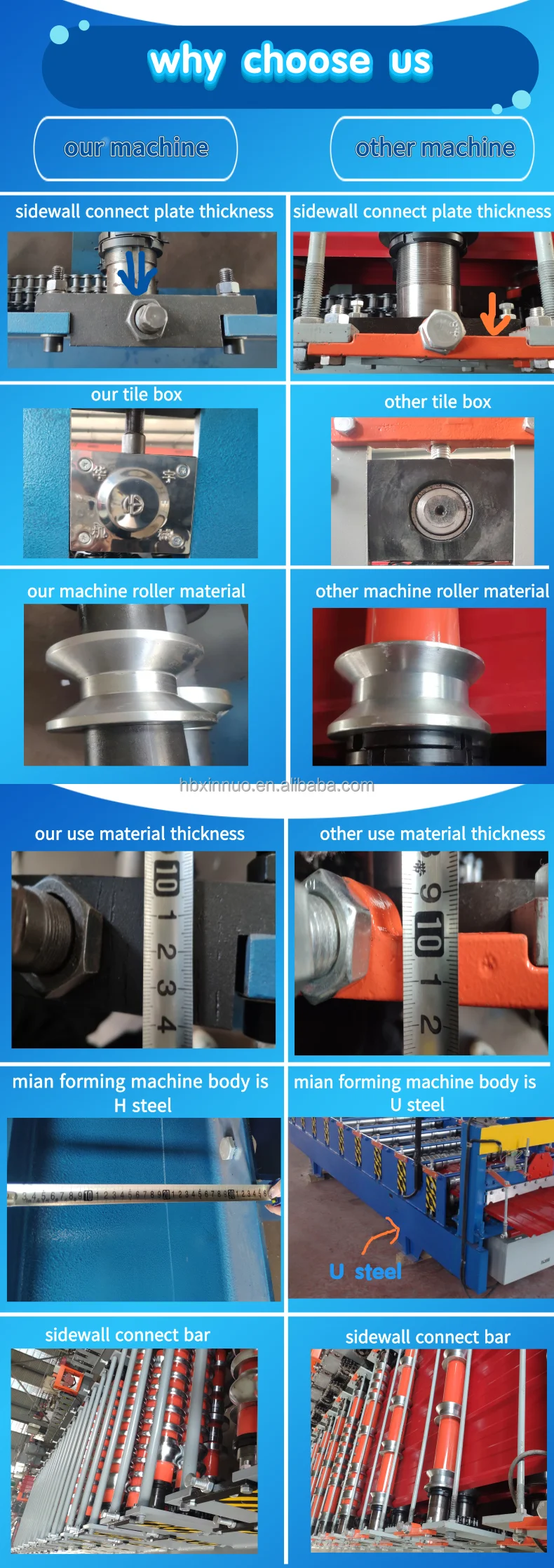

I-Hebei Xinnuo Roll Forming Machine Co., Ltd., ayikhiqizi nje kuphela izinhlobo ezahlukene zemishini yokwenza ama-roll, kodwa futhi ithuthukisa imigqa yokukhiqiza ehlakaniphile eyenza umqulu othomathikhi, imishini ye-C&Z yomumo we-purline, imigqa yomshini wokwenza i-highway guardrail roll, imigqa yokukhiqiza iphaneli isangweji, ukudeka. Imishini yokwakha, imishini yokufaka i-keel elula, imishini yokwenza izicabha ze-shutter slat, imishini yokukhipha amanzi, imishini yokufaka udoti, njll.

Izinzuzo Zokwenza I-Roll Ingxenye Yensimbi

Kunezinzuzo ezimbalwa zokusebenzisa ukwenza ama-roll kumaphrojekthi akho:

- Inqubo yokwenza umqulu ivumela imisebenzi efana nokubhoboza, ukuchopha, nokushisela ukuthi kwenziwe emgqeni. Izindleko zomsebenzi kanye nesikhathi sokusebenza kwesibili kuyancishiswa noma kuqedwe, kunciphisa izindleko zengxenye.

- Amathuluzi e-roll form kuvumela izinga eliphezulu lokuguquguquka. Isethi eyodwa yamathuluzi efomu lokugoqa izokwenza cishe noma yibuphi ubude besigaba esiphambanayo esifanayo. Amasethi amaningi wamathuluzi ezingxenye ezihlukene zobude awadingeki.

- Inganikeza ukulawula okungcono kwe-dimensional kunezinye izinqubo zokwenza insimbi eziqhudelanayo.

- Ukuphindaphinda kungokwemvelo enqubweni, okuvumela ukuhlanganisa kalula izingxenye ezakhiwe emkhiqizweni wakho oqediwe, nokunciphisa izinkinga ngenxa yokwakhiwa kokubekezelelana “okujwayelekile”.

- Ukwakhiwa kwamaroli ngokuvamile kuyinqubo yesivinini esiphezulu.

- Ukwakhiwa kweroli kunikeza amakhasimende ukuqedwa okuphezulu kwendawo. Lokhu kwenza umqulu ukwakha inketho enhle kakhulu yezingxenye zensimbi engagqwali zokuhlobisa noma izingxenye ezidinga ukuqedwa njenge-anodizing noma i-powder coating. Futhi, ukuthungwa noma iphethini kungenziwa kugoqwe ebusweni ngesikhathi sokwenza.

- Ukwakhiwa kwamaroli kusebenzisa izinto ngokuphumelelayo kunezinye izinqubo eziqhudelanayo.

- Amajamo akhiwe ngama-roll angathuthukiswa ngezindonga ezincanyana kunezinqubo eziqhudelanayo

Ukwakhiwa kwamarola kuyinqubo eqhubekayo eguqula insimbi yeshidi ibe yijamo eyenziwe ngobunjiniyela kusetshenziswa amasethi alandelanayo amaroli ahlanganisiwe, ngalinye elenza izinguquko ezikhulayo kuphela efomini. Isamba salezi zinguquko ezincane efomini iphrofayili eyinkimbinkimbi.

-

umshini wokwenza umqulu kathayela

-

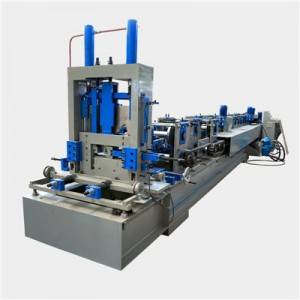

Umshini wokwenza umqulu we-CZ purlin

-

Uhlaka olungezansi lomshini wokwenza i-shutter door roll

-

umshini wokwenza iphaneli elendlalelo ezimbili

-

C21 uhlobo lwethayela cindezela Iphaneli yophahla roll eyenza i-mac...

-

umshini wokulinganisa

-

i-hudraulic decoiler

-

umshini wokwenza i-gutter roll

-

umshini wokwenza i-shutter door roll

-

othomathikhi ishidi decoiler amathayela wokusika m...

-

othomathikhi roll ukwakha umshini amanani umgqomo cor...

-

Uhlaka oluzenzakalelayo lwe-t-grid yensimbi emise okwebha yensimbi...

-

isitaki esizenzakalelayo

-

othomathikhi ishidi decoiler amathayela wokusika m...

-

c profile steel roll ukwakha umshini auto cz s...

-

c umshini we-purlin